Corn Waste to Advanced Biomaterials: Mines and Dakota BioWorx Launch New Bioprocessing Partnership

South Dakota Mines and Dakota BioWorx have launched a first-of-its-kind effort in South Dakota to turn corn stover, the leftover stalks and leaves from corn harvest, into high-value biomaterials that could someday be used in advanced medical applications.

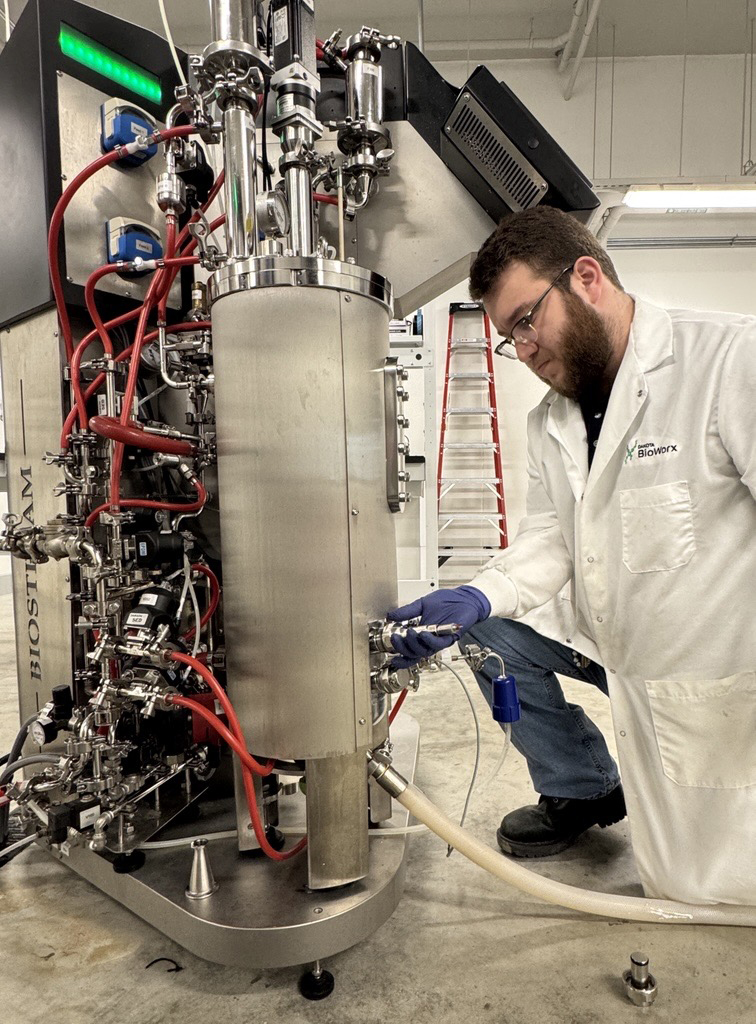

The collaboration unites Mines’ MASON research team, led by Professor Rajesh Sani, Ph.D., with Dakota BioWorx’s new industrial bioprocessing facility in Brookings, S.D. Together, the partners are creating one of the nation’s first thermophilic biomaterial biorefinery models in a step that positions South Dakota as an emerging hub for sustainable biomanufacturing.

“South Dakota has an incredible opportunity to turn agricultural residues into next-generation materials,” said Sani. “This partnership shows how regional strengths in agriculture and biotechnology can come together to build entirely new industries.”

Turning Crop Residues into New Economic Value

Corn stover is one of the largest untapped agricultural byproducts in the U.S. By pairing thermophilic microbes with engineered biomaterial processes developed at Mines, the team is converting this low-cost feedstock into bio-based materials that could support future medical uses such as soft-tissue interfaces, drug-delivery systems, and other biomedical innovations.

Production began last month inside Dakota BioWorx’s pilot facility, where 30-liter

fermentation runs are now underway. The team plans to scale to larger industrial volumes in the coming months.

This “bench-to-industry” pipeline is designed to accelerate how university research

moves into real-world manufacturing.

underway. The team plans to scale to larger industrial volumes in the coming months.

This “bench-to-industry” pipeline is designed to accelerate how university research

moves into real-world manufacturing.

“This work represents exactly the kind of value-added biomanufacturing South Dakota is ready for, taking something abundant in our rural economy and turning it into something with national and global demand,” said Craig Arnold, CEO of Dakota BioWorx.

Benefits for Students, Industry, and the State

The partnership also creates hands-on learning opportunities for Mines students in areas such as fermentation, bioprocess engineering and biomaterials testing. These skills are increasingly needed in the region’s growing biotech workforce.

The project strengthens South Dakota’s rural economy by sourcing local feedstock and keeping commercialization and scale-up opportunities within the state.

Advancing a New Class of Biomaterials

The materials produced through this collaboration will be refined into nanogels–soft, tunable biomaterials with potential medical and therapeutic uses. Future research will focus on performance testing and validating how these materials behave in biomedical environments.

“This is a blueprint for how states like South Dakota can lead future U.S. manufacturing,” Sani said. “Not by importing technology, but by building new technologies grounded in our own regional strengths.”

This effort builds on Mines’ established leadership in composite and biomaterial research through the Composite and Nanocomposite Manufacturing-Biomaterials Center (CNAM-Bio) and the CAPE Laboratory. The CNAM-Bio bioprocessing center, opened in 2023, enables researchers to scale technologies from lab discovery to pilot production.