Mines Partners with Idaho National Lab on AI-Driven Project to Cut Energy Use and Advance Clean Energy

South Dakota Mines is partnering with Idaho National Laboratory (INL) on a new Department of Energy project aimed at making clean energy more efficient, affordable and sustainable for the future.

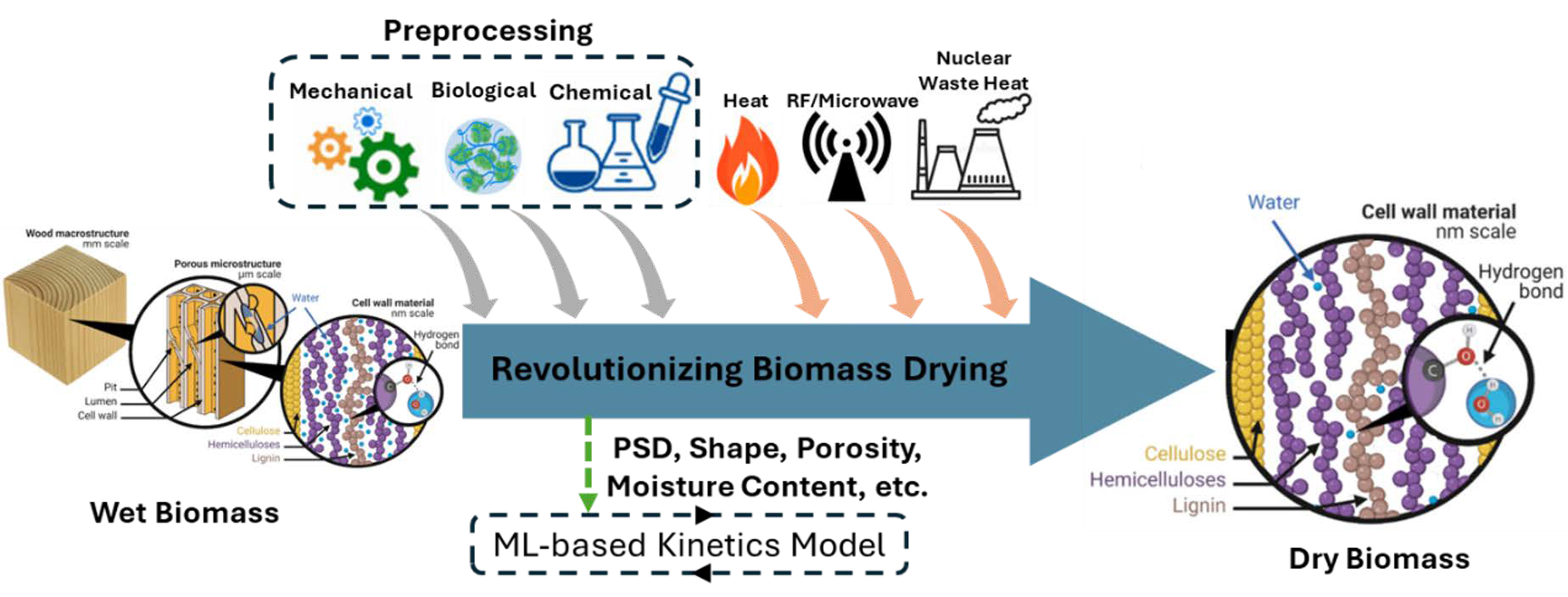

The two-year project focuses on improving biomass drying, a critical but energy-demanding

step in producing fuels and bioproducts from plant-based materials such as agricultural

waste and forestry residues. Currently, drying biomass can account for more than 70

percent of the total energy needed before these materials can be turned into usable

energy products.

By combining advanced artificial intelligence (AI) developed at Mines with cutting-edge energy research at INL, the project seeks to dramatically reduce energy use, lower costs and make renewable energy technologies more practical at large scales.

“Biomass has enormous potential as a clean energy resource, but the process of preparing it is often inefficient,” said Kazi Khoda, assistant professor of chemical and biological engineering at Mines. “Our goal is to help make renewable fuels more accessible by cutting down the energy required to produce them.”

The research team, which includes Khoda and Nepu Saha, a research scientist at INL

and principal investigator, will explore new drying methods that use recovered waste heat, including

that from nuclear power plants, and pair those techniques with AI-based predictive

models. Khoda’s research group, PRocess Optimization, Design InteGration, and Informatics PRODIGI, will develop physics-informed machine learning models capable of determining how

moisture moves through plant materials and identify smarter ways to dry biomass using

less energy. These AI tools will help researchers and industry partners optimize processes

before they are built, saving time, money and resources.

investigator, will explore new drying methods that use recovered waste heat, including

that from nuclear power plants, and pair those techniques with AI-based predictive

models. Khoda’s research group, PRocess Optimization, Design InteGration, and Informatics PRODIGI, will develop physics-informed machine learning models capable of determining how

moisture moves through plant materials and identify smarter ways to dry biomass using

less energy. These AI tools will help researchers and industry partners optimize processes

before they are built, saving time, money and resources.

“Collaborating with INL allows us to merge world-class experimental science with our expertise in physics-informed AI,” Khoda said. “This collaboration strengthens South Dakota Mines’ role in national clean-energy research and demonstrates how trustworthy, high-fidelity AI can accelerate discovery in bioprocessing, materials and energy systems.”

The project will support student training and workforce development, giving Mines students opportunities to collaborate with INL and to work on federally funded research aligned with national energy priorities. Students and early-career researchers will gain hands-on experience in clean energy innovation, data science and advanced manufacturing applications.