NSF Grant Fuels Research Advancements at Mines with Cutting-Edge Equipment

A nearly $700,000 National Science Foundation-funded piece of cutting-edge equipment will help South Dakota Mines researchers accelerate scientific discoveries.

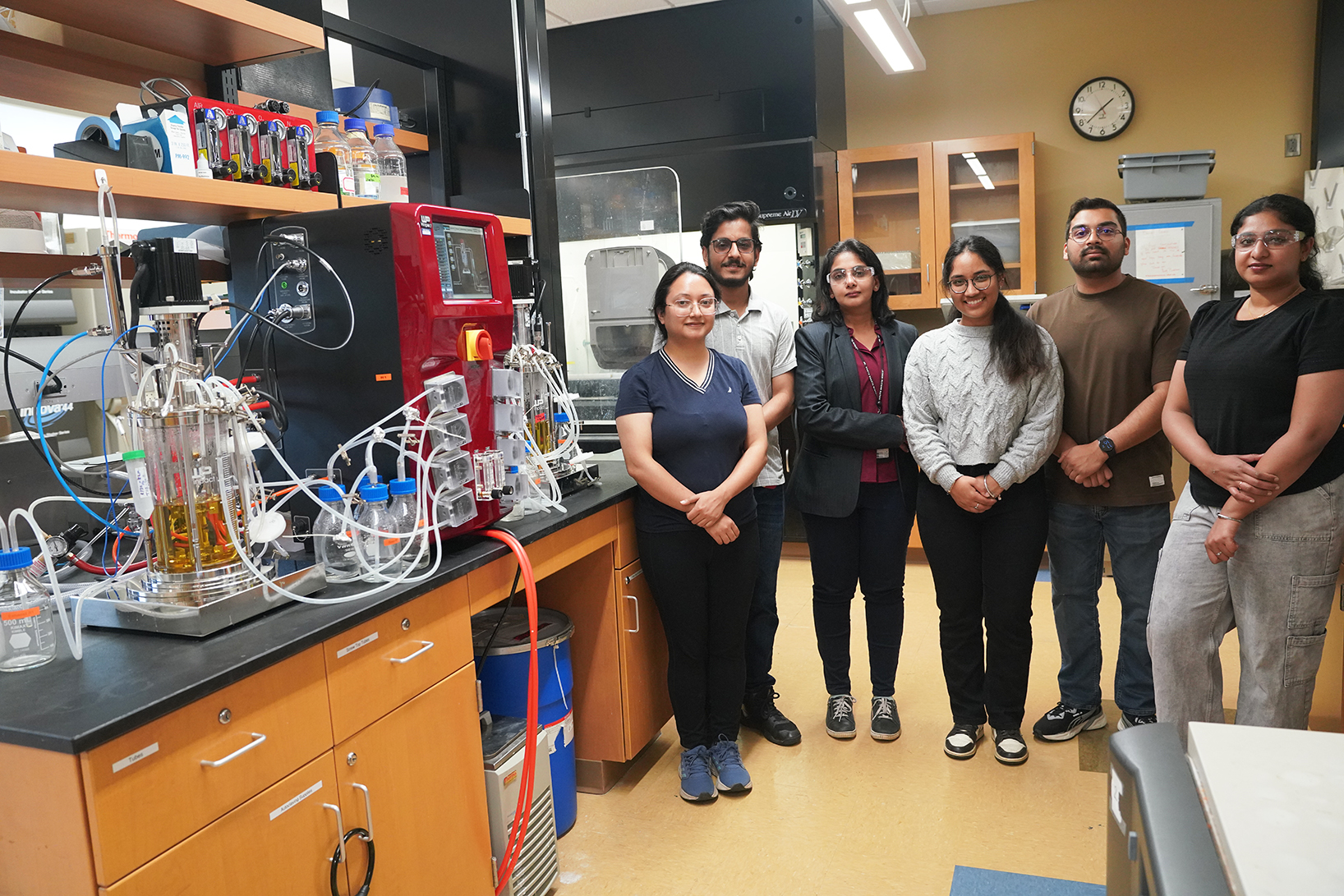

By the end of the semester, the university hopes to have its BioLector XTM microbioreactor system in its new home in the Karen M. Swindler Department of Chemical and Biological Engineering.

Currently, researchers can study only one or two microbes at a time using large-volume bioreactors. The new system will allow them to simultaneously grow and monitor up to 48 miniature microbial cultures in real-time, measuring key parameters such as growth, oxygen levels, pH and cellular responses, all without interrupting the experiment.

“What makes this system special is its ability to replicate the conditions used in large-scale industrial fermentation, like stirring, air flow, and how nutrients are delivered, but at a very small scale,” said Tanvi Govil, Ph.D., assistant professor in the department and lead principal investigator for the NSF award.

The current equipment uses liters of liquid for the bioreactors; with the new equipment, each culture uses just one milliliter, allowing researchers to run more tests with less material and waste.

“This not only reduces material and operational costs but also helps de-risk scale-up by generating high-quality, real-time data early in the process. It also provides detailed, continuous data that traditional shake flasks or older systems simply cannot,” Govil said.

Govil and Rajesh Sani, Ph.D., Mines professor, recently returned from Yellowstone National Park where they collected samples of thermophilic cyanobacteria for a separate NSF grant. “With the new system, we can now test all strains simultaneously, dramatically accelerating their research timeline,” Sani said.

The new system will help Mines scientists work smarter and faster.

“It will enable us to explore a broad range of microbes – from those that thrive without oxygen to photosynthetic organisms that use sunlight – so we can optimize how they produce useful products like biodegradable plastics, protein-based medicines, eco-friendly biofertilizers and clean biofuels,” Govil added.

In addition to product development, the system will accelerate discoveries in synthetic biology, bioremediation, microbial and biomedical engineering. Researchers will be able to design and test biological systems faster, identify microbes that clean up pollutants, and engineer strains for medical or agricultural use. The data-rich capabilities of the system also support education and training – from engaging K–12 students with hands-on science demonstrations to preparing college students and future biotech professionals with the latest tools used in industry.

“The microbioreactor will be a shared resource, supporting faculty-led research across multiple departments at South Dakota Mines and expanding collaborations with institutions including Oglala Lakota College and South Dakota State University,” Govil added. “This award reflects the collective effort of several faculty members who envisioned this capability, and we are deeply grateful for their support and contributions.”

With this new technology, Mines researchers will be able to explore more ideas, test solutions faster at lower costs and make discoveries that could shape the world and build a more skilled STEM workforce.