Karen M. Swindler Department of Chemical & Biological Engineering

Chemical engineering encompasses a vast range of industries and applications, bridging the gap between molecular science and large-scale production. Chemical engineers design and optimize processes that power modern life – from developing artificial organs and advancing biomedicine to producing bioenergy and manufacturing microprocessors. Whether focused on sustainability, efficiency, or cutting-edge materials, chemical engineers play a vital role in turning scientific discovery into practical, real-world solutions.

Department Overview

American Institute of Chemical Engineers (AIChE)

We are the student chapter of the American Institute of Chemical Engineers at South Dakota Mines. Our mission includes:

- Creating opportunities for networking with professionals and students

- Education outside the classroom

- Facilitation of faculty and student interaction

- Increasing campus and community awareness of chemical engineering

Contact Information

If you would like to get in touch with the AIChE or attend our meetings, contact our AlChE chapter president at aiche@mines.sdsmt.edu or check out our Instagram page.

Innovation Club for Engineers

Our mission is to provide entrepreneurial resources and opportunities to students of the School of Mines as well as members of the community via weekly high-value meetings and semesterly conferences.

Dept. of Chemical and Biological Engineering

SD Mines Campus - Chemistry and Chemical Engr Bldg

501 E. St. Joseph Street

Rapid City, SD 57701

The bachelor of science program in chemical engineering at Mines is accredited by the Engineering Accreditation Commission of the Accreditation Board for Engineering and Technology:

ABET, Inc.

415 N. Charles Street

Baltimore, MD 21201

Telephone: 410‐347‐7700

Fax: 443‐552‐3644

E‐mail: accreditation@abet.org

http://www.abet.org

Chemical Engineering Educational Objectives

Through the baccalaureate degree, South Dakota Mines students are prepared to become practicing chemical engineers ready to enter the workforce and make immediate contributions. This program produces graduates who can perform at a level that meets or exceeds industry expectations. Within a few years of graduation, graduates should have the characteristics described by the following educational objectives:

- Ability to apply fundamental and practical knowledge of unit operations, thermodynamics, reaction engineering, process control, and design of safe, economical, and sustainable chemical/biological processes

- Successfully employed and advancing in governmental and industrial positions requiring chemical engineering expertise

- Prepared to succeed in graduate and professional programs

Chemical Engineering Student Outcomes

Based on the program's educational objectives, several student outcomes have been established. At the time of their graduation, Mines graduates have the characteristics described by the following student outcomes:

- Ability to identify, formulate, and solve complex engineering problems by applying principles of engineering, science, and mathematics

- Ability to apply engineering design to produce solutions that meet specified needs with consideration of public health, safety, and welfare, as well as global, cultural, social, environmental, and economic factors

- Ability to communicate effectively with a range of audiences

- Ability to recognize ethical and professional responsibilities in engineering situations and make informed judgments, which must consider the impact of engineering solutions in global, economic, environmental, and societal contexts

- Ability to function effectively on a team whose members together provide leadership, create a collaborative and inclusive environment, establish goals, plan tasks, and meet objectives

- Ability to develop and conduct appropriate experimentation, analyze and interpret data, and use engineering judgment to draw conclusions

- Ability to acquire and apply new knowledge as needed, using appropriate learning strategies

Through cooperative education (co-ops) and internships, students are employed by industry and government agencies in positions related to chemical and biological engineering. All Mines students are encouraged to have relevant work or research experience prior to graduation.

Co-ops are often 6-8 months (semester + summer), and students keep their full-time student status during their co-op semester. Internships are usually for the summer or part-time during the school year. (The terms are often used interchangeably by employers.)

Students may earn 1-3 hours of academic credit for their co-op or internship experience, subject to department approval.

The average co-op/intern salary for 2023-24 was $22.45/hr.

Some employers also provide housing allowances, bonuses,

and relocation expenses that are not reflected above.

We strongly encourage students to seek out these opportunities. Students who spend two or more academic terms working for an industrial partner gain a better understanding of exactly what it's like to work as a chemical engineer in industry. Students often secure permanent job offers from their co-op companies. Even if they don’t, co-op experience is an asset when students begin to interview for jobs after graduation. For questions regarding co-op opportunities within the CBE department, please contact the co-op advisor, Dr. Kenneth Benjamin.

More Information

Sample Employer Evaluation Form

Contact

Dr. Kenneth Benjamin

(605) 394-2636

Kenneth.Benjamin@sdsmt.edu

Karen M. Swindler (ChemE, '88) had more than 25 years of experience in the chemical industry and was one of the only women in charge of manufacturing for an S&P Fortune 500 company, LyondellBasell.

She credited South Dakota Mines for giving her a practical education, enabling her success in life. She gave back to the university through volunteering: recruiting students; presenting to university classes and organizations, including as a keynote speaker at the regional AIChE conference; serving on the Chemical Engineering Advisory Board; and serving on the Alumni Association Board of Directors, including a term as president from September 2017 until she passed away in July 2018.

A generous gift made by Lee Swindler and his family honors Karen's memory as well as her contributions to the field of chemical engineering and South Dakota Mine.

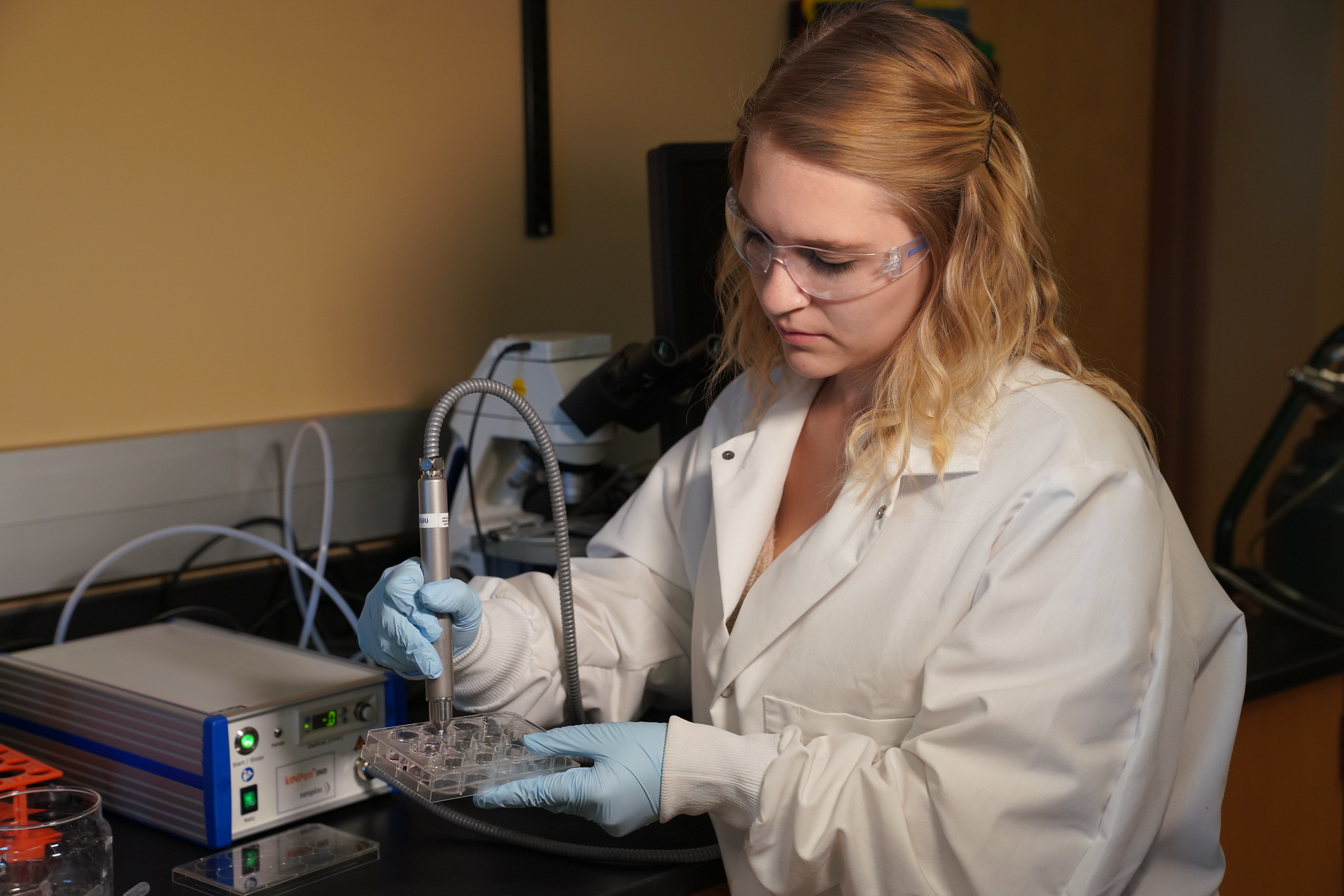

Chemical and biological engineering students have access to a wide variety of state-of-the-art instruments and laboratories, including:

Analytical Laboratory

FT-IR spectrometer with microscope

FT-IR spectrometer with Attenuated Total Reflection (ATR) system

Laser-Raman spectrometer

HP 6890 gas chromatograph

Others (UV-Vis spectrometer, AA, ICP, Ion chromatograph)

Bioseparations Laboratory

AKTA Explorer FPLC Purification System

Waters UPLC

Zetameter size/charge analyzer

Streaming potential analyzer

Reverse osmosis filtration unit

Ultrafiltration/microfiltration units

High Performance Computing Cluster (shared with Department of Physics)

49 Nodes/568 CPUs Total

2100-2600 MHz Processor Speeds

Software includes Accelrys Materials Studio, VASP, Gaussian, LAMMPS, Towhee, Etomica,

CHEMKIN, and Comsol

Mechanical and Thermal Testing Laboratory

MTS mechanical tester

Setaram microcalorimeter

Cincinnati micron injection molding machine

Microscopy Laboratory

Scanning electron microscope with energy dispersive X-ray and image analyzer (SEM/EDX)

Transmission electron microscope (TEM)

Atomic force microscope (AFM)

Interfacial force microscope (IFM, one of a half dozen in the world)

Process Design and System Analysis Computer Laboratory

IBM RISC / 6000 workstations

AspenPlus model manager (steady state process simulator)

AspenPlus speedup (dynamic simulator)

HYSYS process (steady state and dynamic process simulator)

Personal computer laboratory (Gateway 2000 Multimedia Pentium computers)

HSC software

Process Control Laboratory

Camile 3000 controller and data acquisition system

Reaction and Separation Engineering Laboratory

Combustion synthesis reactorCentrifugal combustion synthesis reactor

SHS reactor

Supercritical extractor

Supercritical equilibrium and variable volume view cell

Supercritical reactor

The Chemical and Biological Engineering Seminar Series features leading experts on a wide range of topics. Presentations take place on Tuesdays at 4 p.m. during the fall and spring semesters. Details are sent via email to the campus community.

Research Labs & Centers

The world is continually in need of energy to power our ever-growing population and infrastructure. Given supply concerns with traditional fossil fuels, developing sustainable and renewable energy is crucial. Department research in this area focuses on new applications of chemical reaction engineering, chemical engineering separations, novel solvents and solvent mixtures, and materials development.

The ultimate vision for a bio-processing plant involves the conversion of renewable biomass sources into energy and fuels, as well as value-added chemicals and products. Chief among these value-added products are materials, such as polymers, for use in mechanical and structural applications.

Biomedical engineering combines research in medicine, biology, and engineering to design and create innovative devices and processes, such as drug delivery systems, for the human body.

Historically, chemical engineers are trained to design and optimize chemical processes. The goal of this research is to chemically transform one or more raw materials into one or more valuable end-products.

Whether developing new catalytic or energetic materials, designing bioreactors, or characterizing reaction mechanisms, catalysis and reaction engineering are central to the activities of chemical engineers, as well as process and product development.

Engineers process a wide array of multiphase materials that include additions such as polymers, surfactants, colloids, and particulates.

In addition to experimentation, computer simulation and modeling are crucial components in research. Department activity in this field involves the application of finite element modeling to transport phenomena, as well as molecular modeling and simulation investigations of materials, combustion, and catalysis.

The skills chemical engineers possess not only equip them to design new chemical and biological processes for commercial production, but also to design and engineer systems to aid the environment.

Developing viable solutions for the improved production of bioenergy, biofuels, biochemicals, and bioproducts requires research at the interface of molecular biology, microbiology, and chemical engineering.

Nano-scaled materials offer numerous application possibilities and several advantages over their traditional macro-scale counterparts. Department research focuses on the use of nano-catalysts for water splitting and fuel chemistries, the synthesis of nano-energetic materials, and the synthesis and characterization of nano-composites for materials applications.

Department research focuses on the development, characterization, and testing of polymers and polymer nanocomposites for various systems and applications. It is facilitated by the Center for Advanced Polymer Engineering and the Composite and Nanocomposite Advanced Manufacturing Center.

Chemical and physical separations are indispensable as part of a chemical engineering process. The ability to selectively remove or separate a desired product or molecule from one or more undesired products or constituent molecules is a crucial step in several industries, including biochemical, energy, environmental, and pharmaceutical technologies.

Thermodynamics is the study of the equilibrium behavior of matter, including the determination of properties of solids, liquids, and gases, their mixtures, and their application in chemical engineering processes.

Contact Us

Program Assistant I

Chemical & Biological Engineering Department (CBE)

CBEC 2202

(605) 394-2421

Michelle.Valko@sdsmt.edu

Have more questions?

Dr. Rajesh Shende

CBEC 2207